Comprehensive Welding Inspection Service for Industrial Projects

Comprehensive Welding Inspection Service for Industrial Projects

Blog Article

Unlocking the Key Types of Welding Providers for Your Projects

In today's landscape of varied welding solutions, recognizing the subtleties and applications of various welding techniques is vital for effective task execution. From commonly utilized techniques to innovative modern technologies, the world of welding supplies a spectrum of possibilities to provide to various task needs. By deciphering the key kinds of welding services available, one can browse the complexities of choosing the most suitable technique to make sure precision, efficiency, and quality in welding jobs. As we embark on this exploration of welding services, a much deeper insight into the world of welding awaits, appealing understandings that can elevate the outcomes of your jobs.

Common Welding Strategies

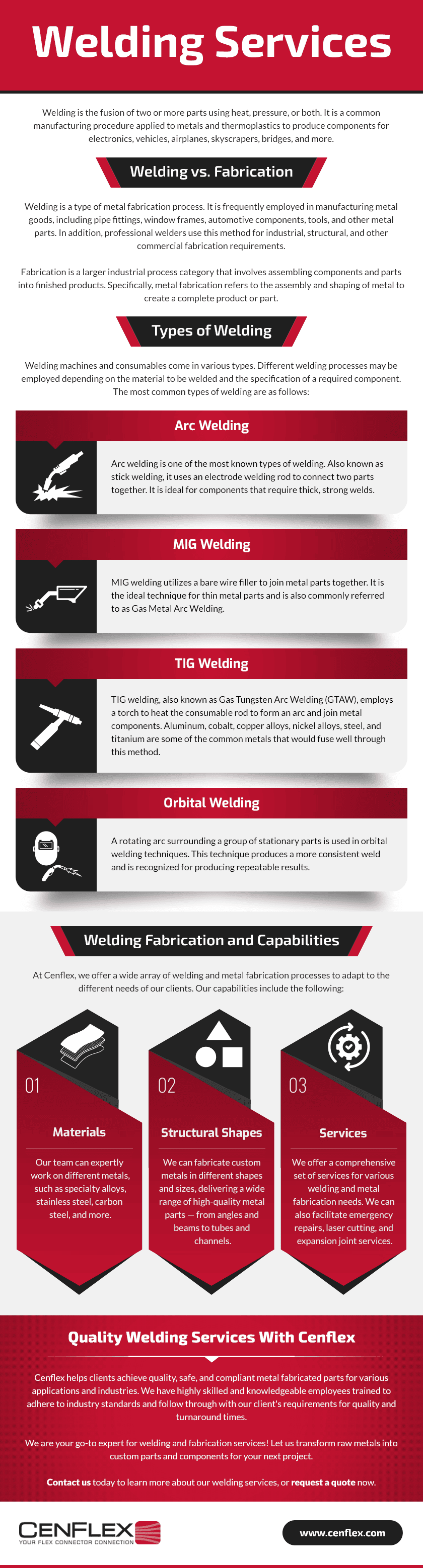

A number of commonly made use of welding strategies play crucial roles in different commercial industries. Among the most extensively made use of methods is Gas Metal Arc Welding (GMAW), likewise understood as MIG welding. This technique includes feeding a cord electrode through a welding weapon, which is linked to a power source and shielded by a gas blend to secure the weld pool from atmospheric pollutants. GMAW is valued for its versatility, high welding speeds, and capacity to weld various steels.

Another prominent welding strategy is Gas Tungsten Arc Welding (GTAW), commonly described as TIG welding. TIG welding utilizes a non-consumable tungsten electrode to develop the weld and requires a different filler product. This method is preferred for its capability, accuracy, and control to produce premium welds on slim materials.

Shielded Steel Arc Welding (SMAW), or stick welding, is an additional vital technique where a flux-coated electrode is made use of to create the weld. SMAW is known for its simplicity, convenience, and viability for on-site and exterior welding applications. These common welding methods are necessary for fabricating frameworks, machinery, and numerous equipment throughout markets.

Advanced Welding Procedures

Advanced welding processes incorporate sophisticated methods that push the boundaries of conventional welding approaches in terms of adaptability, efficiency, and precision. One such process is laser beam welding, which utilizes a concentrated beam of light to sign up with steels with very little heat-affected zones, making it suitable for delicate or high-precision tasks. Furthermore, electron light beam welding utilizes a high-velocity electron beam to produce deep welds in thick materials, providing phenomenal strength and high quality.

Furthermore, friction stir welding is a solid-state signing up with process that makes use of a rotating device to create frictional heat, bonding materials without thawing them. This approach is especially useful for signing up with light-weight alloys with premium mechanical residential or commercial properties. An additional innovative method is ultrasonic welding, where high-frequency ultrasonic vibrations are used to create solid-state welds in plastics, steels, and various other materials, providing tidy and fast joining services.

These advanced welding processes deal with a varied series of commercial requirements, providing reliable, premium, and accurate remedies for different tasks, from aerospace elements to vehicle parts and beyond.

Specialized Welding Applications

Automated Welding Solutions

In contemporary industrial settings, the implementation of automated welding options has actually revolutionized manufacturing procedures by enhancing performance and precision. Automated welding systems use advanced innovations such as robotics, computer numerical control (CNC), and man-made intelligence to perform welding tasks with minimal human intervention (Welding Inspection Service). These systems offer numerous benefits, including raised performance, enhanced weld quality, and reduced production expenses

One secret advantage of automated welding solutions is their ability to consistently produce high-quality welds, bring you could try these out about enhanced general item quality. Furthermore, these systems can operate constantly, 24/7, without the demand for breaks, leading to greater outcome levels and faster project conclusion times. By using automated welding options, business can also alleviate the dangers connected with human mistake, making certain higher precision and repeatability in the welding procedure.

In addition, automated welding remedies are adaptable and extremely functional to numerous welding applications, from complex parts to large-scale frameworks. Whether in vehicle production, aerospace markets, or construction jobs, the assimilation of automated welding systems offers an one-upmanship by simplifying procedures and delivering superior welding results.

Cutting-edge Welding Technologies

The development of automated welding remedies has actually led the way for the integration and improvement of innovative welding innovations in modern industrial applications. One such innovative technology is laser beam of light welding, which makes use of a very concentrated beam to sign up with steel parts with accuracy and effectiveness. This technique is especially helpful for jobs needing intricate welds on materials with high melting points or for applications where minimal heat-affected areas are critical.

Another ingenious welding modern technology getting popularity is rubbing stir welding (FSW), a solid-state joining process that produces high-strength bonds by generating frictional warm in between two items of steel. FSW is widely used in sectors such as aerospace and automobile for its ability to produce welds with exceptional mechanical residential or commercial properties and improved structural integrity.

In addition, electron beam welding (EBW) is an innovative strategy that makes use of a beam of high-velocity electrons to develop precise, deep welds in steel parts. This innovation is preferred for its capacity to weld dissimilar steels and materials with differing densities effectively. As sectors remain to demand greater top quality and performance in welding procedures, these ingenious innovations are poised to play a significant role in shaping the future of industrial welding applications.

Conclusion

In conclusion, comprehending the essential kinds of welding services is essential for efficiently finishing a variety of tasks. From usual welding strategies to advanced processes, specialized applications, automated solutions, and cutting-edge modern technologies, each approach supplies one-of-a-kind benefits and applications. By familiarizing yourself with these various welding alternatives, you can choose his comment is here one of the most ideal method for your certain job demands and achieve top quality outcomes.

In today's landscape of varied welding solutions, comprehending the nuances and applications of different welding techniques is vital for effective job execution. By deciphering the crucial kinds of welding solutions available, one can navigate the complexities of choosing the most suitable method to make certain accuracy, efficiency, and high quality in welding projects. As we begin on this expedition of welding services, a deeper insight right into the globe of welding waits for, appealing insights that can raise the results of your tasks.

Report this page